Equivalent to research of “NTM” assessment on neo plastic cells in terms of in-vivo and in-vitro, a linked research was applied on relevant drugs through the new system.

Associated drugs are combined in two main parts: one acts as a carrier that has tendency to absorb in to the certain malignant tumor, another transfers via carrier to the neo-plastic cells, meanwhile specific “NTM” drugs act similar to all type of malignancies. Evidently, nuclear medicine kits were also used as a carrier for this complex. At present, for several groups of tumors, NTM are available, consequently that allowed the clinical practice of drugs on some volunteer patients.

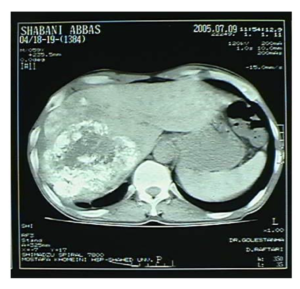

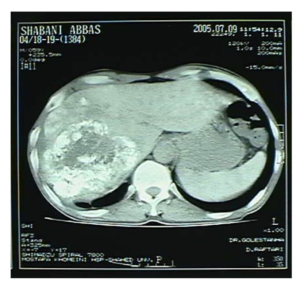

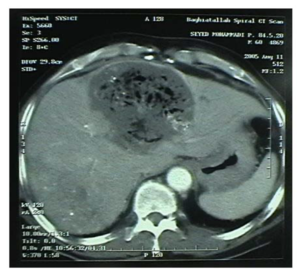

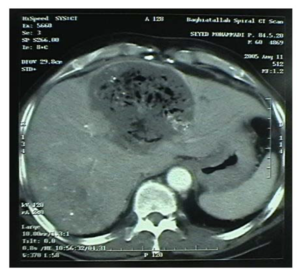

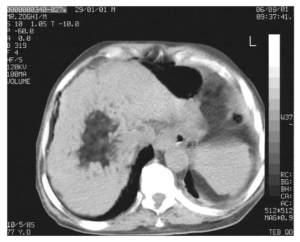

However, Ethic Commission of Medical Science University authorized us that at the first stage of clinical practice, we should enforce the new procedure only on the patient who would suffer hepato cell carcinoma. There by, we submit, in brief explanation, relevant C.T. Scanning image evidence of some patients.

With no exception, all the patients who were referred to treat by new method were despaired from the other methods, because of the end stage condition. For relative less incident of this disease (hepato cell carcinoma), in addition to treating physician’s written verification compulsion to confirm volunteer patients hopelessness from the other current procedures, hence number of the specimens was less.

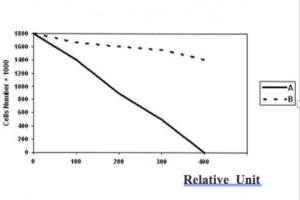

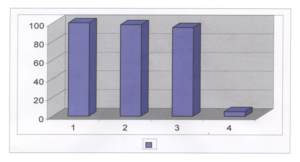

Without exception all patients’ malignancy was undergone to complete necrosis, nevertheless the patients are not to be confined to bed

through this new procedure, hence it would be thoughtful of our therapeutic system privilege.

Specialist simply applies relevant tumor “Radio-Radio Generator Drugs”-by monitor control -on the day clinic-referring patient. After being assured to transfer the optimal amount of drug in to the certain tumor, he expose the tumor by local beam within one to three minute then releases the patient, whilst patient is schedule for only one session treatment.

In later stage, the patient is to set up under periodical care at home, besides CT Scanning investigation at the certain time. The submitted volunteer patients CT Scanning evidence, clearly shows the definite effectiveness of the new method. However, these patients were in the worst clinical condition, after one session of “NTM” procedure, their sickness relatively diminished, hence their appetite turn acceptable, their weight increased in addition to their motility, and physical movement ability improvement.

The malignancy necrosis is explicit for volunteer patients by imaging confirmation, meanwhile, all patients’ identification with their associated CT Scanning, before and after procedure are enclosed.